Manufacturing is no longer about excess paper-forms and excel spreadsheets. Processes are now being digitized, with digital twins of all documents and everything is connected via the internet of things. All important files are being created, sent and received on tablets or mobile devices worldwide and even offline.

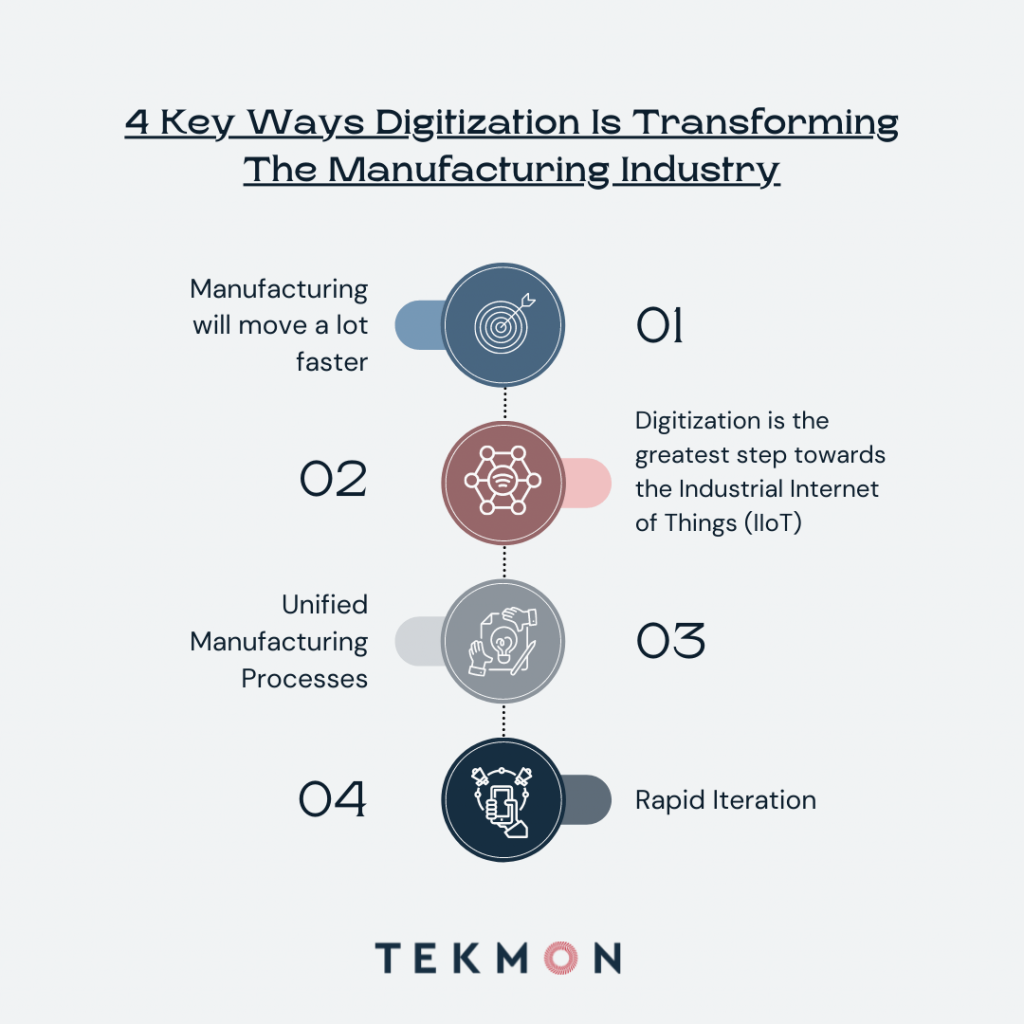

This article highlights the 4 key ways in how digitization is transforming the manufacturing, and what it means for the businesses in the manufacturing industry.

Okay but WHAT is Digitization?

In layman’s terms, the process of digitization is taking non – digital formats of information (paper forms)and ‘digitizing’ them into digital formats that are easily accessible on all electronic devices. The most comforting aspect of digitization for organizations, is that this digital process does not affect processes or alter them in any way.

The manual paper forms aspect of processes are now just digital forms. So how does digitization really transform the manufacturing industry?

#1. Manufacturing will move a lot faster

As digitization transforms the manufacturing industry, it adds to the speed of manufacturing.

Manufacturing needs to adapt to rapid changing consumer taste, acceleration of new products being introduced as well as new innovations. Without this, there’s no auto-check and no opportunity for further innovation to optimize processes.

Digital transformation provides the manufacturing industry with an instant boost to productivity, allowing for processes to move at a heightened speed, to track and achieve all deadlines successfully. Currently with processes being manual, there is a higher chance of human error which adds to completion time and the success of projects.

Digitization makes this process more efficient by solving these problems. This then opens the door for modern manufacturing innovation.

#2. Digitization is the greatest step towards the Industrial Internet of Things (IIoT)

The most important thing when it comes to business is data. Data that can be collected and leveraged to the progression and success of an organization.

The Industrial Internet of Things (IIoT) refers to interconnected sensors, instruments, and other devices networked together with computers’ industrial applications. These devices provide constant data and information that is vital for operational processes, e.g. maintenance requirements, wear and tear etc.

All this information aids in the manufacturing processes to run smoothly and can help to introduce other process refinements. Further refinement can be BI tools and dashboards etc, providing businesses the ability to thoroughly analyze data and maintain efficiency.

Ultimately, we arriving at a milestone where automation and AI continuously streamline existing processes in light of real life demands, resulting in more time and energy for engineers to focus on new innovations.

#3. Unified Manufacturing Processes

A key struggle to consider when it comes to manufacturing, is that major problems occur with analog processes when manufacturing across several different locations. Yet manufacturing is seen as a global industry, this is where digitization can offer much needed ease for global manufacturing chains.

One reason digitization can offer relief is with the ease of sharing vital data. Sending data via email is not as secure or efficient as sharing files and data across a centralized work network. This eliminates the vulnerability of company data. Also, digitization can help both with clarity but also with process enforcement. For example, specifying that every field in a form needs to be completed.

With digitization of forms etc, you have mandatory fields that need to be filled, in order to increase compliance. This makes sure that all manufacturing processes are unified throughout the whole business and at every location, avoiding any errors that can cause inconsistencies or inconveniences.

#4. Rapid Iteration

Digitization won’t just make manufacturing more efficient. It also, based on current trends, drives development through rapid production iteration. Improved data sharing across teams, associations etc will only accelerate this iteration speed. Making sure that data is accessible in real time at any location worldwide, resulting in organizations to act on innovation trends, market opportunities, and consumer demands better than ever.

Digitization is just the beginning…

Digitization is just the beginning of a great story of digital transformation, with the introduction of digitization many more innovations can be implemented and introduced to add to the success and value of any organization within this fast paced industry and demands of consumers.

Inspired by the concept of flexibility and tailored solutions, Tekmon’s rapid, no-code digitization solution makes complex processes simple and more essential, user-friendly without diminishing the effectiveness and efficiency of processes in order to make sure organizations are at the forefront of any industry.