What exactly do we mean by ‘digital transformation’ beyond the general investment in new technologies? How is he evaluated in a company? Which sectors of the economy do best and where does the Industrial sector rank among them ?

A simple and clear method to measure the degree of digitization of a company is to look at three sub-areas: digital property, digital utilization and work digitization.

- The Digital Assets (Assets) include all the proprietary technologies and digital information of the company. From computers, software, telecommunications equipment, robots and drones to digitally interconnected equipment. That is, how much the company has invested in the market and development of technologies.

- The Digital Utilization (Usage) is about whether digital property really improves the back office and front office processes of the company, as well as its relationship with customers and suppliers. For example, how well ERP has been adopted, how CRM is implemented, how digital payments are used, how effective digital marketing and social media are, how many choose automated customer support.

- Finally, The Digitization of Labor (Labor)concerns the productivity of the company’s employees and whether they use digital tools in every aspect of their daily activities. Relevant indicators that show the degree of digitization of work, is the investment made by the company per employee in hardware and software, as well as the percentage of processes performed by employees through digital tools.

It has been repeatedly proven that the companies that lead in their industries are significantly better in the last 2 sectors. In other words, they make better use of the technologies in which they invest, and give digital tools to their employees to be more productive.

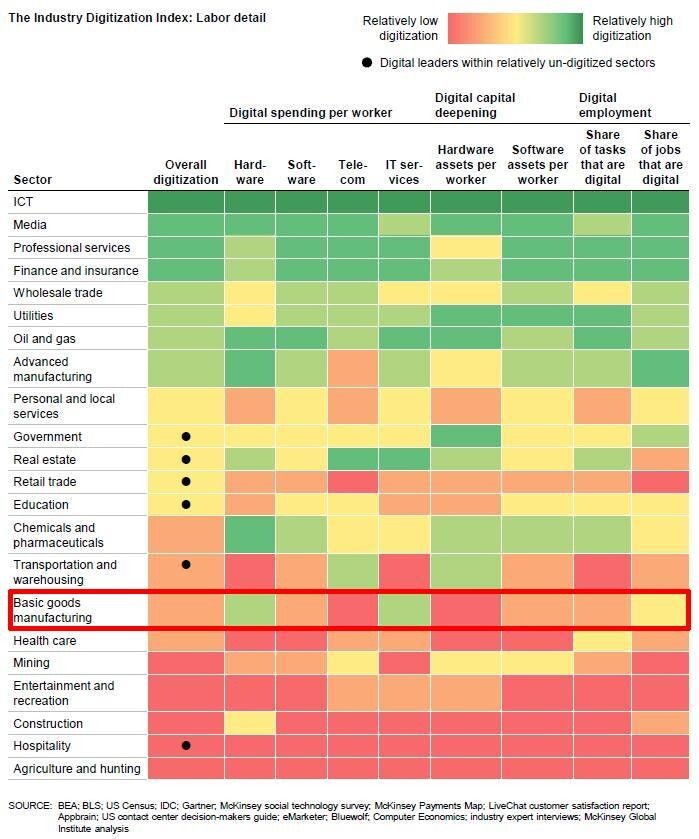

Harvard University, in collaboration with the McKinsey Global Institute, regularly conducts research that measures the degree of digitization of different sectors of the economy. As shown in the two graphs below, specific sectors such as Technology, Media and Financial Services, show great maturity in all areas of digital transformation. Others, such as those of Industry, Commerce, Transport, Warehousing and Construction, have lagged behind.

The industry sector especially seems to operate at 2 speeds. On one hand we find advanced manufacturing (advanced manufacturing), which includes the manufacture of electrical equipment and appliances, the automotive and aerospace industry which seems to be above average. Yet, on the other hand the basic industry ( basic goods manufacturing ) which includes all rest and is located at the lower end, just above construction, agriculture and hospitality.

But why is this happening? In other words, why do certain sectors of the economy systematically adopt new technologies at a faster pace than others?

If we look closely we will see that in the industries that are low in the digital spectrum, including basic goods manufacturing, the majority of the staff works from the field. In other words, they are not bound by a stable job and are constantly on the move. The work environment is much more demanding and the adoption of technologies by employees is significantly more difficult.

ERPs is what the vast majority of industries have adopted, however it has a major weakness. Although they are extremely effective in automating accounting, procurement, sales, inventory (WMS) and payroll processes, they can be a headache when they enter more productive areas such as quality control, maintenance and health and safety. They are difficult to use, they require specialized users, the implementation times are very long and in almost every phase of the implementation the involvement of the IT department is necessary.

At Tekmon, we develop software specifically designed for such environments and for these employees. Our goal is for our solutions to be easy to use and understandable to all users. We believe that managers should have the ability and flexibility to create, configure and implement digital processes themselves, without depending on their implementation by the IT department.

A typical example of the use of our technology is that of the London Underground (LU) . More than 1,500 technicians performing maintenance work on the train tracks, before starting their shift, were crowded daily in containers to be informed about the work and the special conditions of the space where they were to work.

Now, via Tekmon’s platform, managers create their own work instructions, upload helpful images, drawings and videos, group employees into shifts and send targeted updates. The technicians monitor the updates at their own pace directly from their mobile phones and automatically generate the necessary permit to enter the construction site.

Tekmon’s technology is helping the London Underground (LU) close the digital divide in the field of job digitization, which translates into both saving hundreds of man-hours for the company and a real upgrade of daily life for the employees themselves.